NDT - Non Destructive Testing

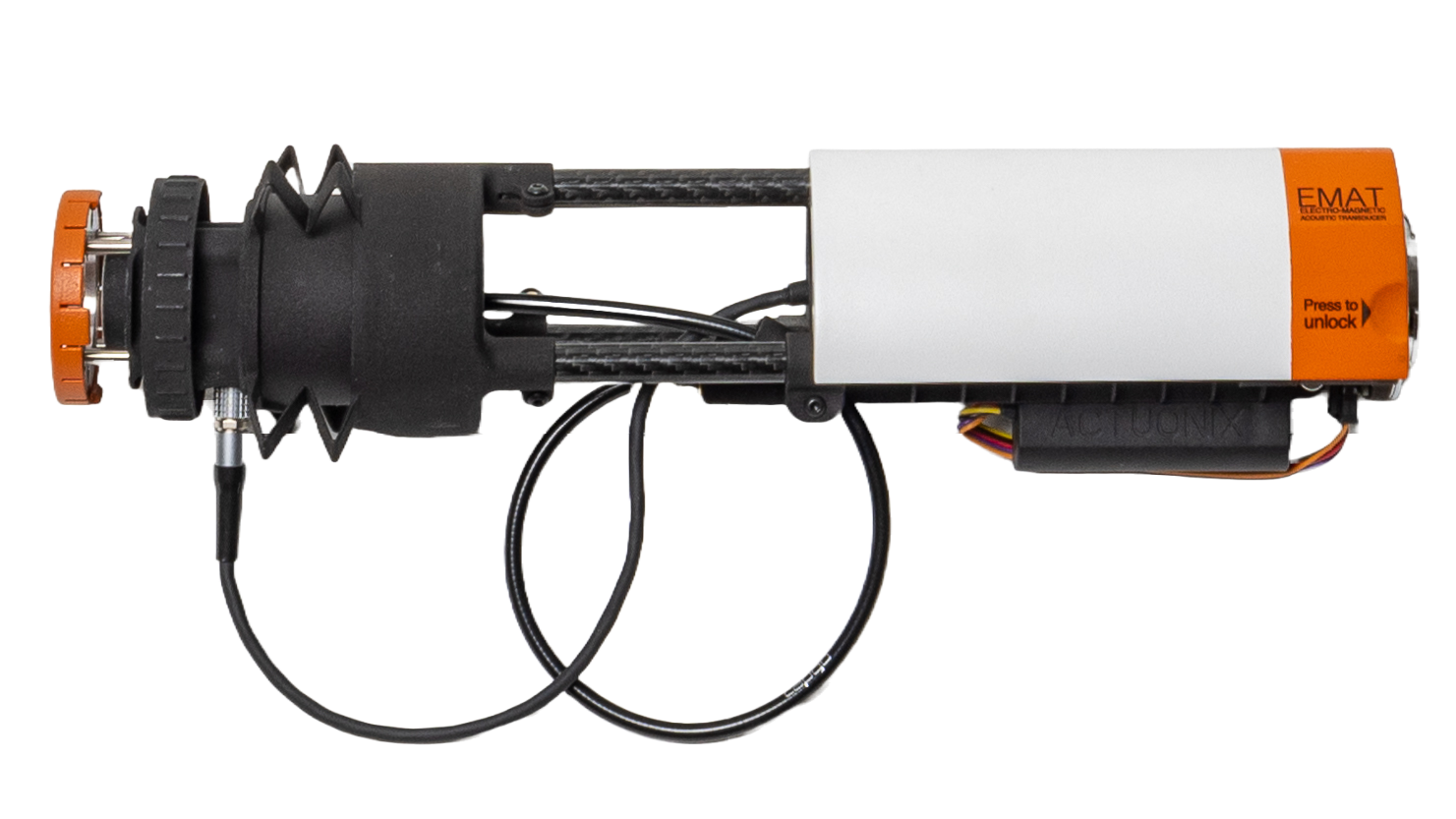

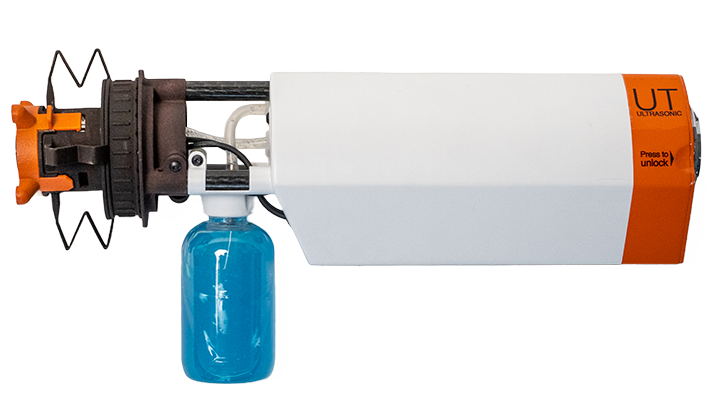

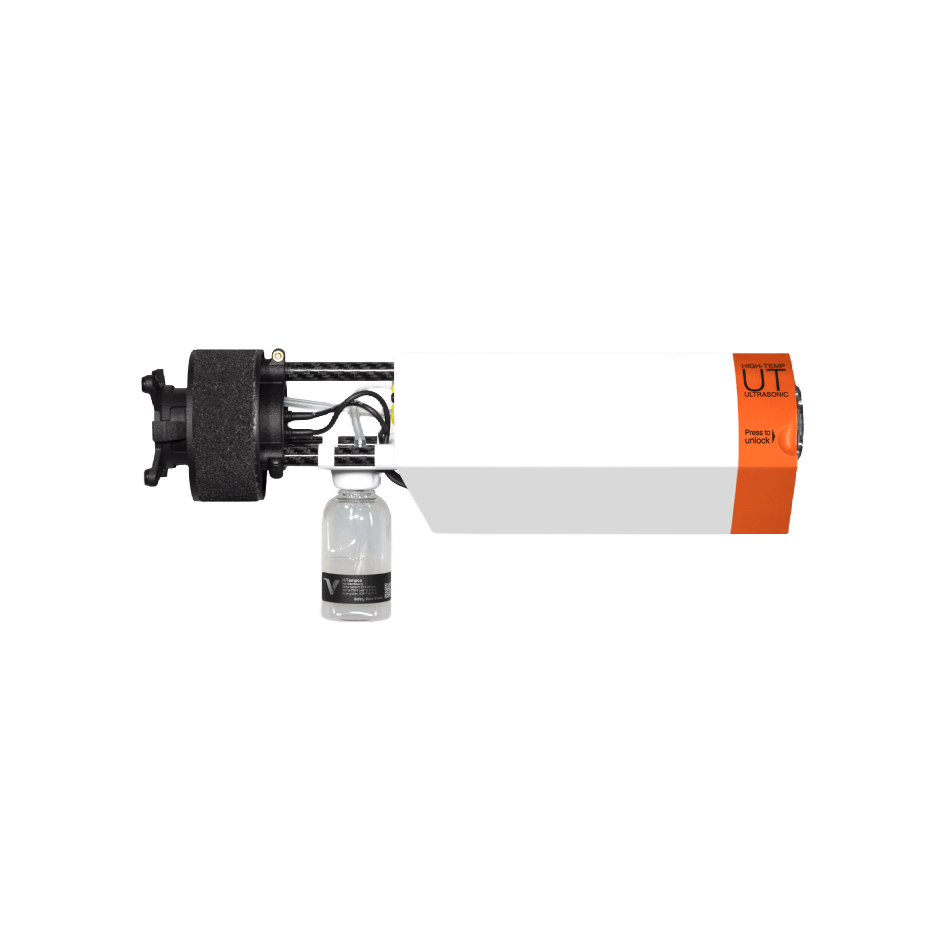

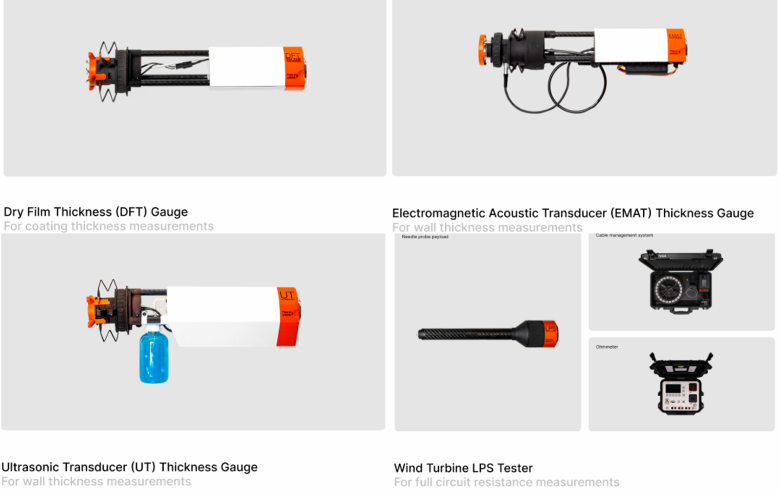

UT / EMAT / DFT / LPS

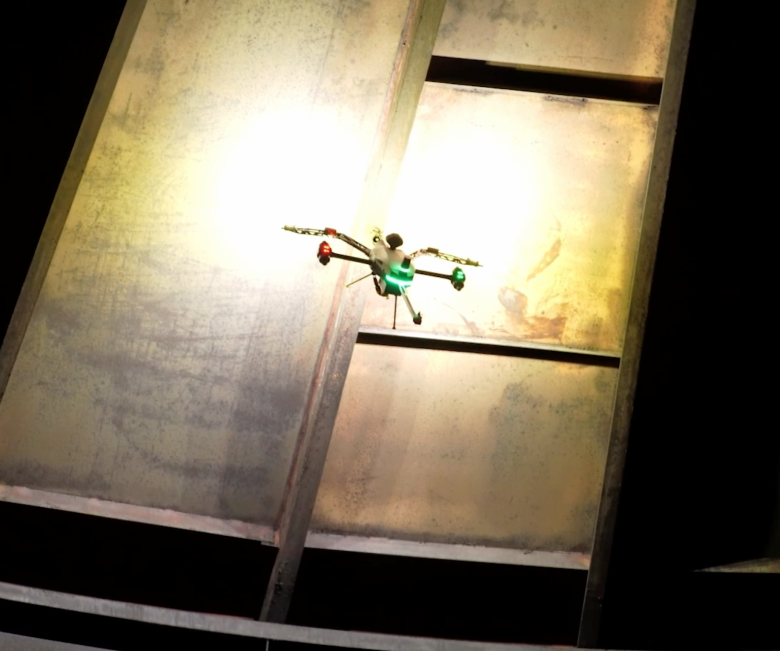

Inspection of assets at height and from any angle.

Perform the same work safer and more cost-effective

Safety is our first priority

Optimize Shutdown Efficiency

Maximize the utilization of shutdown time by conducting comprehensive inspections within the planned time frame.

Early Problem Detection

Identify and address potential issues proactively by inspecting all assets, ensuring uninterrupted operations.

Minimize Downtime

Prevent unnecessary downtime and production delays by inspecting assets while in service.

Arial roboting

Highly reliable even in closed environments

Storage tanks commonly suffer from corrosion, erosion, and material degradation, which can compromise their integrity and safety. Regular inspections are crucial to detect and address these issues promptly.

Multiple payload system

Different asset types - No problem

Our system has different payloads, that enables us to do multiple measurements depending on the material and temperature of the asset.

Live QC - Easy reporting

Swift sharing of data through easy reporting

Our pilot focuses on flying, our NDT specialist focuses on the meassurements.

Safety and quality is key.

Advantages for asset owners

Improving every step of Non- Destructive Testing

Process with our system:

Receive an inquiry

Evaluate the scope of work

Perform on-site inspection

Deliver the inspection report

Process with conventional

testing methods:

Receive an inquiry

Evaluate the scope of work

Define and mobilize the appropriate teams

Arrange equipment logistics

Coordinate on an available lead-time for all parties

Align on a suitable schedule for all involved parties

Set up equipment for the pre-inspection phase

Perform on-site inspection

Manually process inspection data

Deliver the inspection report

What to inspect

Sensory based asset types that would benefit greatly from aerial NDT

Customers

Trusted by brands with purpose

Have questions? - Ask us!

Write or call us:

info@wefly.dk

Phone: +45 7199 2491